Iodized salt production business can be initiated as small scale basis with comparatively small startup capital investment. The manufacturing process is simple, producing iodized salt by iodinating common salt. India is the third largest salt producing country in the world after the US and China. The present demand for the iodized salt is estimated at 281,514 tonnes per annum. The demand is expected to reach 413,412 tonnes by the year 2020.

IODIZED SALT PRODUCTION MARKET POTENTIAL

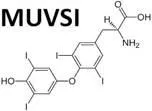

Iodized salt is a white crystalline powder salt fortified by Iodine. Most of the people of the country are at risk of iodine deficiency disorder (IDD) because their soil lacks iodine and because they lack access to foods which contain iodine. IDD can be easily avoided by consuming sufficient amount of salt fortified with Iodine. Salt fortification is a highly cost-effective method of ensuring that everyone receives a steady and continuous iodine supply. Iodized salt improves thyroid function, improves brain function, fights against depression, controls weight and many more. Increasing health awareness and spending capacity of the people are the key factors of the growing market of iodized salt.

IODIZED SALT PRODUCTION BUSINESS REGISTRATION

In starting iodized salt production business, entrepreneurs need to obtain different registrations and licenses from Government Authority in India. These are as follows:

1. Business registration with ROC

2. Trade License from Municipal Authority.

3. Factory License

4. Udyog Aadhaar MSME Registration

5. Food Business Operator License

6. BIS Certification

7. In most of the states, the business doesn’t demand Vat Registration. However, check your state law.

These licenses and registrations must be obtained from respective authorities in India.

FINANCE FOR IODIZED SALT PRODUCTION BUSINESS

Total initial investment cost will depend on your desired production output and total project cost. Broadly, you can categorize the cost in two section. One is fixed capital investment and another one is working capital investment. The fixed capital investment includes land, building and machinery. On the other hand, working capital investment includes raw materials, packaging consumables, utilities, human resources etc. You can apply a loan to any bank and financial institution provided you can accommodate at least 25 – 30% of project cost as collateral security.

IODIZED SALT PRODUCTION MACHINERY & UTILITIES

In starting a medium scale, iodized salt production unit following machinery is required.

1. Silos (stainless steel)

2. Crushers (Roller/ball)

3. Mixers

4. Packing Machines

Electricity is the major utility required as it is used as power source for heavy-duty crushing machines installed in the plant. Water is also required for general purpose in the plant.

IODIZED SALT PRODUCTION PROCESS & RAW MATERIAL

The production programme is prepared based on the selected plant capacity and expected market share to be captured by the unit. At the initial stage of production, the plant may require some years to penetrate into the market. Therefore, the plant initially will operate at 75% of its rated annual capacity. Broadly iodized salt can be produced through the various different process.

Iodising the edible salts with potassium iodide, potassium iodate and calcium iodate, are the most popular production process. Potassium iodide is not stable and, therefore, stabilisers (like calcium carbonate) have to be added to reduce the loss of iodine, in the case of using Potassium Iodide. The iodate, on the other hand, is stable up to 560 Deg C. Except in extreme

The iodate, on the other hand, is stable up to 560 Deg C. Except in extreme conditions, Potassium iodate does not deplete and can sustain even after 300 days in storage as iodised salt. The Central Salt & Marine Chemical Research Institute (CSMCRI), Bhavnagar

The Central Salt & Marine Chemical Research Institute (CSMCRI), Bhavnagar found that it is only on heating the iodised salt or boiling the solution, that there is significant depletion. Potassium iodate has been approved by the Health Ministry for iodinating the salt. According to the 1987 BIS standards, to get 30 ppm of iodine, 50 ppm of potassium iodate needs to be added. To get the iodised salt, the iodate is dissolved in water or saturated brine. Then the salt crystals are mixed with the aqueous solution to form

iodised salt.

| Raw Materials | Specifications |

| Salt | Edible grade |

| Potassium iodate | Technical grade 40 ppm/25 ppm |

Considering the growing demand of the product, iodized salt production business is one of the most profitable investment opportunity in India. The income statement and the other indicators of the profitability show that the project is financially viable.