Barbed wire production business can be initiated as small and medium scale basis with a comparatively small startup capital investment. Galvanized barbed wire is classified into three categories; Classes I, II, and III. Class I has the thinnest coating and the shortest life expectancy. A wire with Class I coating will start showing general rusting in 8 to 10 years while the same wire with Class III coating will show rust in 15 to 20 years. The aluminum-coated wire is occasionally used and yields a longer life. Barbed wire is generally used for security purpose. Barbed wire is very popular for fencing in the construction industry.

BARBED WIRE PRODUCTION MARKET POTENTIAL

Barbed wire is an essential item to safeguard houses, gardens, forests, nurseries and specified prohibited areas pertaining to the defense establishment, aerodromes, railways, warehouses and other Govt. and Private properties. They are also used to make and safeguard international boundaries and are one of the cheapest materials to be used for these various purposes. Growing population, increasing numbers of building and construction, increasing the security issues in the current socio-economic zone, are the major factors of the increasing demand for barbed wire.

BARBED WIRE PRODUCTION BUSINESS REGISTRATION

In initiating barbed wire production business, you will need to obtain several registration and licenses from Government authority.

1. Business registration with ROC. While you are starting a small scale unit, it is recommended to register your business as OPC (One Person Company).Otherwise, you can form LLP, Pvt. Ltd. or Ltd. Company.

2. Obtain Trade License from local Municipal Authority.

3. Apply for Udyog Aadhaar MSME registration

4. Obtain VAT Registration

5. Obtain NOC from state Pollution Control Board

6. Apply for BIS Certification. Certification standard IS: 278-1978 needs to be maintained in the manufacturing process.

INVESTMENT FOR BARBED WIRE PRODUCTION BUSINESS

Fixed capital investment for barbed wire production unit includes the cost of land, building and machinery. You can initiate the manufacturing operation with a rental unit shade. This will minimize your fixed capital investment towards the project. For machinery purchase, you can invest your own capital or apply for the term loan.

Working capital cost includes raw material purchase, rent, human resource, transport cost with other operating cost. You can apply a cash credit to serve the purpose of working capital investment. Else you can apply finance for the entire project. In any case, you will need to arrange the collateral security according to the demand of banks or any financial institution.

MACHINES & RAW MATERIALS FOR BARBED WIRE PRODUCTION BUSINESS

In starting barbed wire production business, you will need to procure some simple machines.

1. Automatic barbed wire making machine

2. Bench grinding machine

3. Universal tensile testing machine

4. Wrap torsion testing machine

5. Weighing scale

6. Testing equipment

The only raw material required is galvanized iron wire 12/14 SWG.

BARBED WIRE PRODUCTION PROCESS

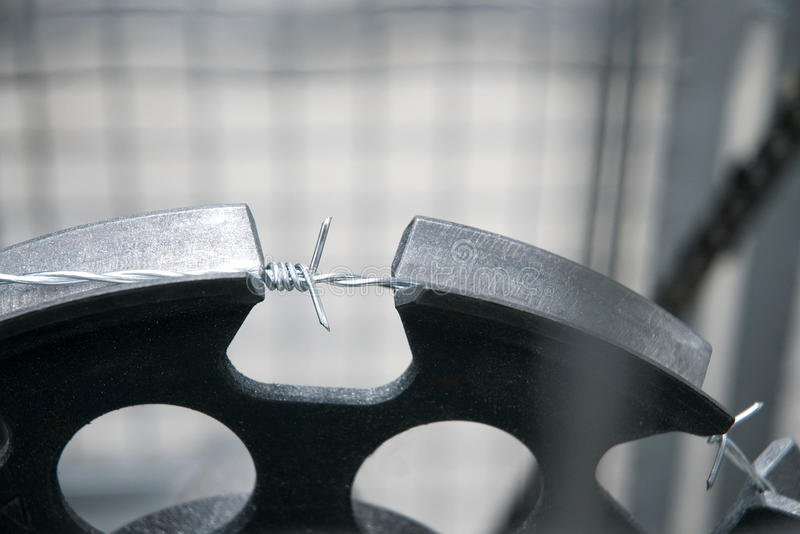

The barbed wires are made on an automatic machine. The barbed wire is made out of 12/14 SWG MS Galvanized wires. While two main line wires are fed into the machines through its axes another wire is fed into the machines through its axes another wire is fed across into the pair of line wires to form barbs at required intervals.

The line wire twines themselves automatically the point wire after forming the desired barbs strands with the line wires automatically at the desired distance thus forming the complete barbed wire. As the machine is automatic all its feeding and wire cutting mechanism is controlled by gear movements, which drive its power from the main

electric motor attached to the machine. Once the machine is set up it goes on working

automatically.

Process Flow Chart

Wire feeding → Tensioning → Twisting → Reeling → Despatch

You can start barbed wire production business as a home based also provided, you have some extra space for the manufacturing operation.