Paper cup making business is one of the most lucrative small scale manufacturing opportunity in India. The paper cup is a disposable item made out of paper and often lined with plastic to prevent liquid leakage or soaking through the paper. It can be made of recycled paper and is widely used around the country. In an economically growing country like India, the demand of paper cup is increasing and thus, it is considered as a profitable manufacturing opportunity for the entrepreneurs.

PAPER CUP MAKING MARKET OPPORTUNITY

Paper cups are generally being used in all sorts of ready to eat products. Paper cups are widely used for hot drinks like tea, coffee and any types of cold drinks or energy drinks also. It is also used in serving customized drinks like lassi, juice etc. There is also an extensive usage of paper cups in serving ice cream, sweet corn, sweet delicacies, and packaged food items. Paper cup sizes available range from 60 ml to 550 ml variants. As paper cups are made out of food grade papers, which are fast expanding substitute to plastic and it families, they are being used now for nearly all catering purposes

The growing demand in the urban and semi-urban markets, opening up of international food chains and the acceptability of quality and eco-friendly products has made the production and distribution of paper cups viable as never before in a country like India.

PAPER CUP MAKING LEGALITIES

In starting paper cup making business first, you must register your firm with Register Of Companies. You will need to obtain Trade License, Health License, Vat and Central Excise Registration, No-Objection from Pollution Control Board, Factory License, EPF and ESI Registration. If you want to use diesel generator set for an optional source of power supply, then you need to apply for special permission from your local District Authority.

PAPER CUP MAKING UNIT SETUP & MACHINES

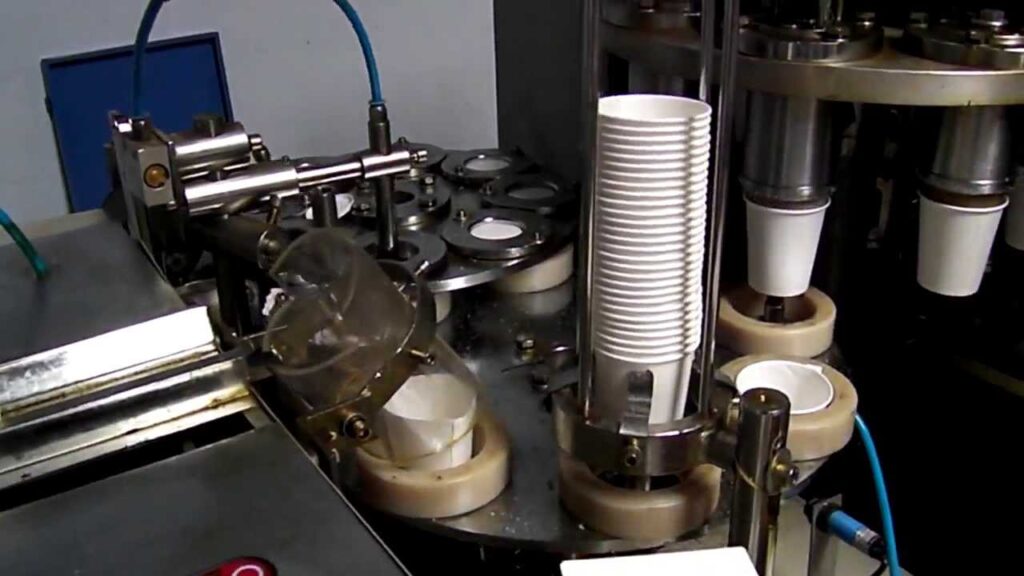

In starting the paper cup making project, it is advisable to have a project report prior. You can setup paper cup making unit by two ways. One is through the semi-automatic process and another one is the fully-automatic process. According to your desired quality and production output, you need to select the machinery. Selecting right machinery is the most crucial factor for any manufacturing business. Establishing machinery that doesn’t fit into your requirement is fatal for any manufacturing business.

In semi-automatic paper cup making unit die cutting machine, paper cup forming machine, printing machine, counting machine and packing machines are generally used. For a fully-automatic setup, you can establish an automatic paper cup forming machine. In every case, proper machine layout planning is important. Such as space for raw material storage, machinery installation, packing unit and finished goods storage. Before placing the purchase order, check testimonials, warranty period and after sell service facility of the machine supplying company.

RAW MATERIAL & PRODUCTION PROCESS FOR PAPER CUP MAKING

PE coated paper roll is generally used for paper cup making. You will get adequate information about the raw material and the supplier of the raw material from your project report.

Die cutting machine is used for cutting the pre-printed sheet paper to cup-fan-wall-body. Through paper cup forming machine paper cups are made. Pack the finished paper cups in plastic bags, and then bags to the cardboard box.

This process is applicable for the PE Coated Sheet Paper and Cup-bottom-roll Paper. In paper cup making you can also set up your own printing section.