Bio-diesel production unit can be established as a small scale basis at any place where the main raw material Jatropha oil is easily available. There is a continuous search for renewable sources of fuels due to the rate of depletion of fossils. The term biofuel is used to define fuels that are obtainable from plants or animals. Being a renewable source, it is gaining attention all over the world today.

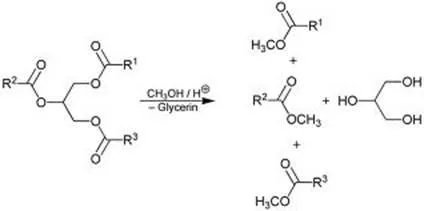

Jatropha Curcus is a large 3 to 4 Meter high shrub, the native of tropical America, occurring throughout India mostly. It kernel yields 46-58 percent by weight of oil, which is 30-40 percent of seed weight. The oil is generally called Circus oil. On Etherification, the oil becomes Bio-Diesel, which is blended with high-speed Diesel from 20 to 80 percent by volume. Transesterified Jatropha Oil blending with Diesel is now a policy adopted by Government of India. The production process is not complex and several universities and institutes are there those have developed the transesterification process of bio-diesel production.

Bio-diesel Production Market Opportunity

The industry experts predict the global biofuels market will double over the next decade, from $82.7 billion in 2011 to $185.3 billion in 2021. According to the new report of Biofuels Markets and Technologies, it estimates steady growth through 2016 but rapid production increases between 2017 and 2021 as a result of higher oil prices, emerging mandates, new feedstock availability, and advanced technologies. Total global biofuel production is projected to reach 65.7 billion gallons per year (BGPY) by 2021.

Various types of engines manufactured today are made to run on a wide variety of fuels, such as premium motor spirit (petrol), diesel, or gas as their primary fuel, with all these types of engines, the diesel engine is the one most suitable to run on biofuel. Also, biofuels are very similar to diesel fuel in composition; therefore, there is no need for engine modification to run on biofuels. Diesel engine burns less fuel producing the same amount of work when compared to a petrol engine. Bio-diesel is a carbon-neutral source of fuel and is increasingly becoming popular.

LICENSE & PERMISSIONS FOR BIO-DIESEL PRODUCTION

In starting bio-diesel production, you must register your firm first and must obtain Trade License from local Municipal Authority. Apart from these you need to apply for following permissions:

1. Factory Licenses: For setting up of any Factory, one needs to take an approval from the District factory Inspectorate.

2. Explosive License: For storage of Methanol, one has to obtain an Explosive License from the Directorate of Explosive.

3. Pollution Control Board Clearance: You must need to have the clearance from Pollution Control Board.

BIO-DIESEL PRODUCTION UNIT SETUP & PROCESS

You can establish bio-diesel production unit by two ways. One is producing bio-diesel from jatropha oil. Another one is producing jatropha oil and then bio diesel from that. For the first option, the main raw material is jatropha oil and for the second one, the main raw material is jatropha seed. Here we will discuss the process and equipment that are used for bio-diesel production from jatropha oil.

Machinery and apparatus used in the production of the biodiesel are as follows: thermometer, retort stand, pipette, measuring cylinder, separating funnel, magnetic stirrer, oven, water bath, hydrometer, conical flask, digital weighing balance, stopwatch, hot plate, distilled water, methanol, and jatropha oil.

Biodiesel Production and Optimization

The bio-diesel production process is carried out using oil in methanol in a shaking incubator at 250 rpm and 45° C for 4 hours.

1. First, dissolve the lye into the methanol. Shake or swirl until all the lye has dissolved.

2. This may take 10 minutes. It is normal that temperature rises. This mixture is called sodium methoxide. Now make sure the J Oil is in a vessel large enough (at least 150% of its volume), preferably with a valve at the bottom, and heat it to about 60 °C, then stop heating. Then add the methoxide mixture and make sure it is mixed well for at least 10 minutes. Leave the vessel and let the different constituents separate by sedimentation

3. The glycerin will settle out at the bottom. After 8 to 24 hours the sedimentation is complete and the glycerine can be drained off.

4. What remains is raw biodiesel. If the reaction went well and the biodiesel is clear, it may be used straight, although its quality may be inferior because of impurities. Water washing will remove most of these impurities.

Methods commonly used for bio-diesel production are batch and continuous processes. In general, smaller capacity plants and variable feedstock quality warrant use of batch systems. Continuous systems generally lead the operation on a 24×7 basis, requiring larger capacities to justify larger staffing needs and also requiring uniform feedstock quality.

This standard prescribes the requirements and methods of sampling and tests for bio-diesel

suitable for fuel in diesel engines. Bio-diesel is a fatty acid alkyl ( methyl or ethyl ) ester

for use as a blend component ( up to 20 percent ) with diesel fuel meeting the requirements of

IS 1460 ‘Automotive diesel fuel — Specification’.