Start a Liquid Detergent Manufacturing Business

Liquid detergent is a type of detergent i.e. cleaning agent. Its popular use is to

wash woolen cloth but it is also used for washing of utensils specially glass and crockery,

and for automobile wash. Now a days it is widely used in washing machines, laboratories

etc.

MARKET :

There are few brands are available in the market which is for woolen cloth

washing. But few MSME units are also having good marketing their products. Considering

the fact that it does not contain any filler material which deposited on the cloth surface, its

popularity is increasing in conscious people. There is good potential of this product of good

quality and economical prices.

BASIS & PRESUMPTIONS :

1. The basis of calculation of production capacity is on single shift basis and

working of 25 days per month.

2. Rate of interest has been taken @ 18% per annum on an average on working

capital and total capital investment.

3. Whereas some names of manufacturers and suppliers of raw materials,

machinery & equipments are at the end of the profile are by no means exclusive

or exhaustive.

4. The cost of machinery & equipments indicated in the profile are approximate

those prevailing at the time of preparation of the profile.

5. Non-refundable deposits of preparation of project report may be considered

under pre-operative expenses.

6. The provision made in raw materials, utilities, overhead etc. is drawn on the

basis of local market conditions/ observations and in approximate. The

entrepreneur may find out the exact cost from the concerned sources.

7. License is required under Drug & Cosmetic Act from state drug controller.

IMPLIMENTATION SCHEDULE

1. Registration of the unit with DIC 10 days

2. Procurement of finance through Bank or 45 days

other financial institutions.

3. Procurement of machines 30 days

4. Commercialization of the unit/ Trial production. 10 days

Process of manufacture :

It is a neutralization process of Acid slurry by Caustic Soda keeping pH 7 to 9. Acid

slurry and water is mixed slowly in the mixer, after that it is neutralized by the aq. Solution of

caustic soda to get the required pH. AOS is used as foam booster while urea is a buffering agent

and also create transparency. Lastly colour and perfume is added.

Quality Specification :

It may be manufactured as per customer’s specification

Production Capacity :

Capacity 75% Capacity

Installed Utilization(I Yr.)

a) Quantity 1,35,000 Kg 1,01,250 Kg

b) Value (in Rs.) 82,83,000 62,12,250

. Power Requirement :

Connected Load : 5 KWH

Pollution Control :

Though there is no discharge of effluent during manufacturing of Liquid detergent but care

should be taken to avoid the chemicals in washings.

Energy Conservation :

The adequate measures for energy conservation and illumination will reduce the wastage of

energy

FINANCIAL ASPECTS :

I. Fixed Capital :

1. Land & Building : (value in Rs.)

Land 200 sq. meter @ 200/- sq.m. 40,000

Covered Area – 150 sq.m. @ 2200/- sq.m. 3,30,000

Rs. 3,70,000

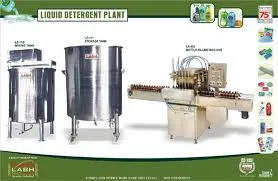

2. Machinery & Equipments :

a) Production unit

Details Qty/No. Price (in Rs.)

1. S.S. Vessel with 1 50,000

stirrer, low speed

Cap. 200 kg

2. Bottle filling machine 1 35,000

.Semi automatic

3. Storage Tanks , SS, 2 30,000

Cap. 200 Liters

4. Tools & Misc. equipments LS 5,000

8. Testing & laboratory equipments LS 20,000

7. Installation & Electrification – 13,500

charges @ 10% of machinery

8. Office furniture, equipment & LS 20,000

fixtures. __________

Rs. 1,73,500

3. Pre-operative Expenses 10,000

Total Fixed Capital :

Rs. 3,70,000 + 1,73,500 + 10,000 5,53,500

II. Working Capital :

1. Personnel :

Designation No. Salary (PM) Total (in Rs.)

1. Manager/ Chemist 1 8000/ – 8,000

2. Skilled Worker 1 5000/ – 5,000

3. Semiskilled Worker 2 3000/- 6,000

4. Sales man 2 3500/- 7,000

26,000

Perquisites @ 15% of salaries 3,900

29,900

2.Raw Material : (PM)

Particulars Qty/kg Rate(Rs) Value(Rs.)

1. Acid Slurry – 80% 2115 85 1,79,775

2. Caustic Soda 220 30 6,600

3. AOS 175 46 8,050

4. Urea 1270 20 25,400

5. Colour 35 400 14,000

6. Perfume 8 600 4,800

7. Plastic bottles & Canes

500 ml cap. 8100 No. 8 64,800

5 litre cap 890 No. 25 22,250

8. Corrugated boxes LS – 10,000

3,35,675

3. Utilities (PM) :

Power and Electricity 1000 KWH @ 6/- 6,000

Water 1,000

7,000

4. Other Contingent Expenses (PM) :

1.Postage & Telephone 2,000

2.Consumable Store 2,000

3.Repair & Maintenance 2,000

4.Transport charges 7,000

5.Advertisement & Publicity 17,000

6.Insurance 1000

7.Sales Expenses 7,000

8.Misc.Expenditure 2,000

40,000

5. Total Recurring Expenditure (P.M.) :

1. Personnel 29,900

2. Raw material 3,35,675

3. Utilities 7,000

4. Other contingent expenses 40,000

4,12,575

6. Total Working Capital ( For 3 months) :

Rs. 4,12,575 X 3 12,37,725

7. Total Capital Investment :

1. Fixed Capital 5,53,500

2. Working Capital (3 months) 12,37,725

17,91,225

Say 17,91,000

8. Financial Analysis :

A. Cost of Production (Per Annum) :

1. Total recurring cost 49,50,900

2. Depreciation on building @ 5% per annum 16,500

3. Depreciation on machinery & equipment @ 10% 14,850

per annum

4. Depreciation on furniture & fixtures @ 20% 5,000

per annum

5. Interest on total capital investment @ 18% 3,22,380

per annum __________

53,09,630

Say 53,10,000

B. Turnover (Per Annum) :

Item Qty.(No) Rate(Rs.) Value(in Rs.)

Liquid Detergent

1. 500 ml 96,000 32.00 30,72,000

2. 5 Litre 10,644 295.00 31,39,980

62,11,980 C. Net Profit(Per Annum) :

(Before Income-Tax)

Rs. 62,11,980 – 53,10,000 9,01,980

Say 9,02,000

D. Net Profit Ratio : 14.50 %

E. Rate of Return : 50.00 %

F. B.E.P. : 43.00 %

Address of machinery manufacturers & suppliers :

1. M/s Singhasini Engg. Works, B- 4/25 , Factory Area, Fazalganj, Kanpur.

2. M/s Golden Engg., A-13, Vishal Enclave, Najafgarh Road, New Delhi.

3. M/s K.S.Krishna & Assocaiates, 15, Community Centre, East of Kailash,

New Delhi

4. M/s Corporated Engg., 7, Chitranjan Avenue, Kolkata

Address of raw material suppliers :

Available with local dealers.

12.Resource Centre of Technology :

Hercourt Butler Technological Institute, Kanpur.

Technical Consultants.